Poor climatic conditions in food production not only affect the quality of the food, but also promote a high level of germ contamination in the air. The resulting consequences are spoiled goods and defective production, which incur considerable costs.

The specially developed ductless HACIS® ventilation system is equipped with UV-C disinfection technology. This results in a continuous reduction in germs and prevents microbiological growth in the form of bacteria, mould or yeast.

Developed in collaboration with:

PGH Engineering Company for Technical Building Equipment mbH

Eremitagestraße 36

95448 Bayreuth

Germany

Tel: + 49 921 5 07 20 67 – 0

Fax: + 49 921 5 07 20 67 – 99

E-Mail: info@pgh.de

www.pgh.de

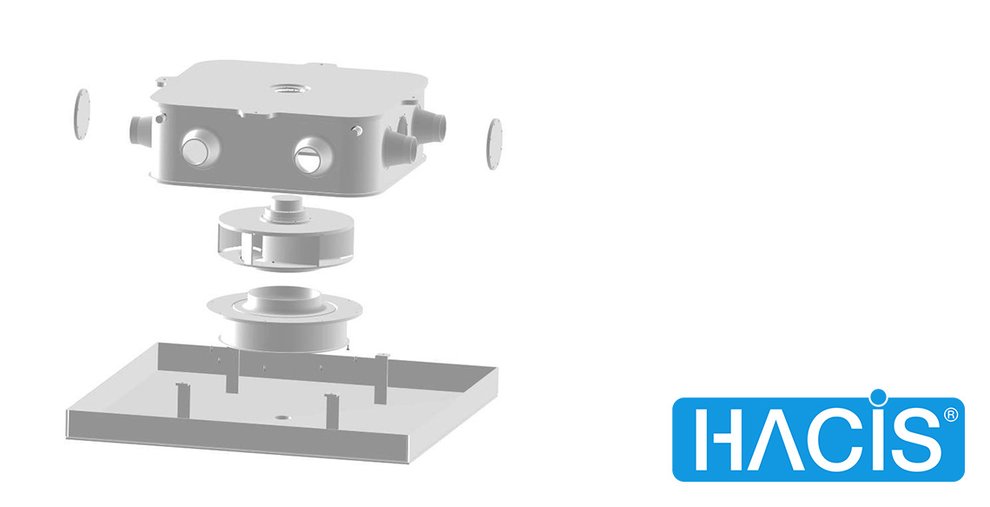

Special fan

HACIS®

Application

- Can be used in all applications for the food industry (food safe)

- for optimal climatic conditions and balanced ripening options in dairy farms

- meets all hygiene requirements of the food industry

- optionally suitable for installation and extraction from ATEX Zone 2 and 1

characteristics

- Volume flow from 500 – 2,500 m³/h

- at a maximum pressure difference of 550 Pa

- available in nominal width 280 mm

| Volume flow | 500 – 2,500 m³/h |

|---|---|

| maximum pressure difference | 550 Pa |

| Efficiency | up to 83% |

| Nominal diameters | 1 nominal width 280 mm |

| operating temperature | 0 – 60 °C |

| Housing material | PP-natural |

| Impeller material | PP-natural |

| drive | Direct drive |

| Atex | Optionally suitable for installation and extraction from ATEX Zone 2 or ATEX Zone 1 in electrically conductive design |

| Connection options | No supply and exhaust air ducts required |

Advantages:

- Use of food-safe PP-natur

- up to 40% lower investment costs

- up to 60% reduced operating costs

- The special design prevents the escape of hazardous radiation

- integrated UV lamp with splinter protection